In the face of mounting challenges, innovations are coming together to complement, augment ‒ and eventually replace ‒ traditional industrial processes, says Assistant Portfolio Manager David Chung.

Key Takeaways

- Industrials have remained relatively resilient through the COVID economic recovery, but the sector continues to face a range of challenges, from labor shortages and shipping disruptions to continued uncertainty about the pandemic.

- Amid these challenges, innovations are being developed that can complement and eventually replace traditional industrial processes that have come under pressure.

- In our view, these technological advances will help industrials overcome near-term hurdles and provide growth opportunities over the long term.

We have previously discussed the effects of the pandemic and the course of recovery in the industrials sector. While the sector has remained relatively resilient, particularly in the early stages of the COVID recovery, it continues to face challenges as the economy works to reopen. Supply chain disruptions, raw material shortages and price inflation, a dearth of qualified labor, rising wages and a multitude of transport troubles have conspired to keep industrial growth dampened and unpredictable. Although economic activity remains strong ‒ the U.S. Institute for Supply Management (ISM) Manufacturing Purchasing Mangers’ Index (PMI) registered 59.9 for August,1 notching a fifteenth straight month of overall economic expansion – these issues, along with a resurgence in COVID cases from the Delta variant, may currently be limiting growth potential.

Long-Term Solutions May Lie in Technology

Adoption of technology accelerated as a necessity during COVID lockdowns, as videoconferencing and cloud computing allowed workers to stay virtually connected, and e-commerce and streaming supplied consumers with remote shopping and entertainment. Likewise, emerging industrial innovations may also provide long-term solutions to the challenges being faced by the sector in the wake of the pandemic.

As manufacturers seek to address recent challenges in productivity and flexibility, advancements in operational technology (OT) have offered potential solutions. OT is the hardware and software that controls various industrial processes and machinery on a factory floor. The increased integration of operational technology and information technology (IT) have allowed for advances such as cloud-based manufacturing execution systems (MES), which can enable a company to track and analyze its operations and supply chains across multiple plants. This connected OT gives manufacturers enhanced ability to manage product quality and compliance, identify potential problems and increase efficiency, offering improvements to the production process and supply chains and adding resilience to their operations.

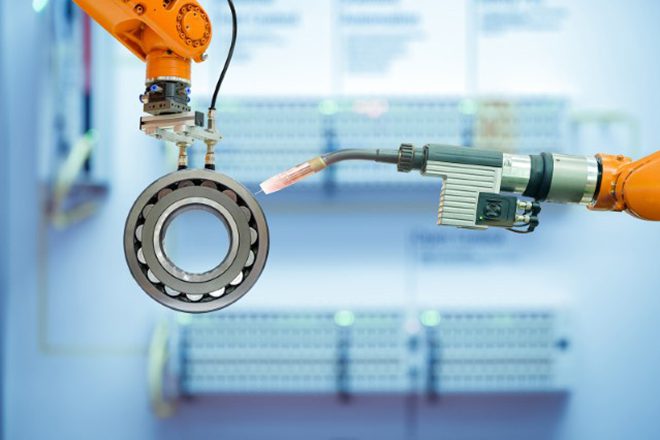

Quantum computing is another area of innovation that in the long term can address some of the logistics and transportation issues currently facing industrials. The sector is still feeling significant effects from the disruptions to trade and travel brought on by the pandemic, and a shortage of qualified labor has added to difficulties in moving goods and materials around the globe. Quantum computing ‒ technology that utilizes processing power exponentially greater than traditional computers ‒ has given companies the ability to solve extraordinarily intricate problems. For instance, as more and more destinations are added to a shipping route, finding the fastest and most fuel-efficient path can become very complex very quickly. The power of quantum computing may allow companies to optimize functions like shipping routes, supply chains and inventories, saving both time and money as they distribute goods throughout their networks. This will likely become increasingly vital as networks become more complex and interconnected. Likewise, innovations such as autonomous trucking and factory automation may serve to address labor shortages and wage pressures, speed shipping and manufacturing times and improve safety throughout these networks.

Though still in the early stages of adoption, technologies like additive manufacturing (AM) ‒ more commonly known as 3D printing ‒ are also beginning to emerge as complements and, potentially, eventual replacements for traditional industrial processes. Critically, AM may allow for increased localization of supply chains, giving businesses the ability to manufacture essential components in-house, become less reliant on scarce or expensive raw materials, and be less dependent on long-distance logistics and transportation for input parts and materials. These issues have become crucial during the deglobalization process – which has been hastened by the pandemic – as links in the global supply chain are moved back to the U.S. and companies seek to create greater resilience in their businesses.

Technological Advances Will Continue to Bolster Growth

While the economic recovery has started to feel some bumps and industrials currently face significant challenges, technologies are emerging that can help to meet ongoing demand and solidify the sector in the future. It is our belief that innovation may lead to broad transformation in industrials, and technological advances will continue to provide long-term growth opportunities in the sector. Importantly, we believe it is essential to remain focused on high-quality, cash flow generative companies that can be long-term winners amid this digital transformation.

1Source: Institute for Supply Management, as of 1 September 21.