Subscribe

Sign up for timely perspectives delivered to your inbox.

Henderson European Focus Trust Portfolio Managers John Bennett and Tom O'Hara discuss how so-called 'sin or dirty' stocks can become sustainable, highlighting Holcim's eco-friendly transformation.

As the global economy grows, the demand for construction materials will only increase. In particular, global cement production is projected to grow to over five billion tonnes worldwide by 2030. This profoundly impacts the overall level of greenhouse gas emissions, as each tonne of cement produces emissions of roughly 0.9 tonnes of carbon dioxide (CO₂).i With net-zero targets firmly in place, cement companies have increasingly come under pressure from strict government regulations and public scrutiny to change their ways. Meanwhile, some investors have chosen divestment or exclusion, riding on the coattails of ‘cancel culture’ to send a strong message to these companies.

These factors have pressured cement companies to modify their business strategies and production processes to promote sustainability. They must focus on making their operations more sustainable to reduce greenhouse gas emissions. One of our portfolio companies that has embraced this challenge and responsibility is LafargeHolcim (Holcim), the world’s largest cement manufacturer. Once a ‘traditional’ cement company, Holcim has become a global leader in innovative and sustainable building solutions.

Holcim’s latest initiative, the 2030 Plan, is a comprehensive Sustainability Strategy designed to encourage the entire construction industry to tackle the issue of climate change and generate shared value for the company, society, communities, and the environment. In line with this goal, Holcim has been implementing measures to enhance operational efficiency and make the cement production process more sustainable, leading to its recognition as one of the most carbon-efficient companies among its global peers. The company’s efforts include radical changes to critical components of its products and offerings to reduce its carbon footprint.

One of Holcim’s primary sustainability goals is to reduce its carbon footprint. The cement industry is a significant contributor to global greenhouse gas emissions, and Holcim is taking steps to reduce its carbon emissions and promote sustainable practices. Holcim has committed to reduce the gross scope 1 and 2 GHG emissions by 25% per tonne of cementitious materials by 2030, compared to its 2018 baseline.1 To achieve this goal, the company is investing in innovative technologies such as carbon capture and utilisation, using alternative fuels and raw materials, and improving the energy efficiency of its operations. However, the most important starting point was cement.

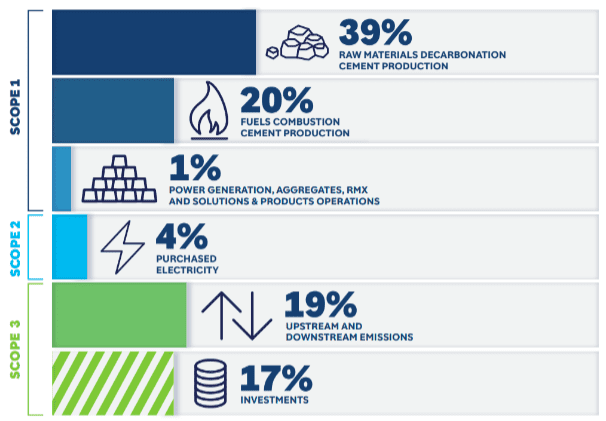

Historically, clinker (the main cement component) production has been responsible for 39% of cement manufacturing’s CO₂ emissions, with fossil fuel combustion necessary to heat the cement kilns contributing 20%.ii In June 2022, Holcim made a groundbreaking achievement by creating the world’s first clinker using solely recycled minerals. This breakthrough paves the way for producing 100% recycled concrete, revolutionising the construction industry, and reducing emissions in cement production for a sustainable future.

Source: Holcim Climate Report 2023

Note: This chart denotes Holcim’s CO₂ footprint

· Scope 1 Emissions = 60% of CO₂ footprint. This includes all emissions released directly from operations. The majority of these come from cement production.

· Scope 2 Emissions = 4% of CO₂ footprint. This includes indirect emissions from the generation of purchased electricity consumed in the company’s owned or controlled equipment.

· Scope 3 Emissions = 36% of CO₂ footprint. This includes all other indirect emissions generated in the supply chain such as transportation and the extraction and production of purchased materials and fuels. Also includes direct emissions from non-consolidate companies and investments.

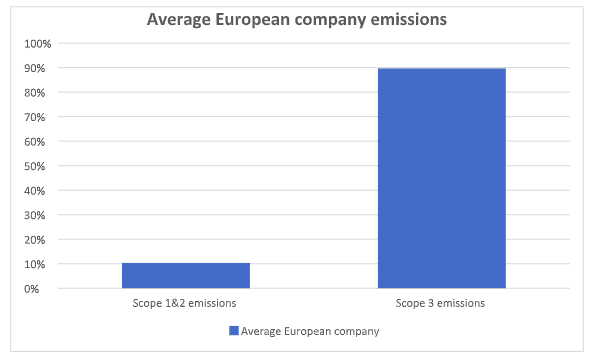

While Holcim’s Scope 1 and 2 emissions receive a lot of attention, its crucial to understand that these emissions are due to the nature of the cement business. So they are going to be higher than the average European company. However, a closer look at the often-overlooked Scope 3 emissions reveals a different story. Compared to the average European company, their scope 3 emissions are relatively low compared to scope 1&2 due to the fact that the production of Cement is very carbon intensive, but once it has left the factory and used in construction it has limited linked emissions. The opposite is true for the average European company; while their Scope 1 and 2 emissions may be low, their Scope 3 emissions are typically much higher as usually more emissions are released at use. (see chart below)

Source: Bloomberg as at 19/04/2023

Holcim is also using alternative fuels and raw materials (AFR) in its cement production processes. AFR includes materials such as industrial waste, biomass, and municipal solid waste, which can be used as a substitute for fossil fuels. By using AFR, Holcim is reducing its carbon footprint and promoting circular economy principles by reducing waste and conserving natural resources. Holcim aims to increase AFR usage to 80% by 2030 and has already made progress, with some of its plants using up to 100% AFR. In addition, the company is also using green energy, such as solar and wind to power its plants whilst exploring next-generation technologies like hydrogen to further reduce carbon emissions.

Holcim is also committed to promoting sustainable building practices. The company’s “green concrete” products, which use recycled materials and are designed for low carbon emissions, have been used in several high-profile construction projects, including the Burj Khalifa in Dubai, the world’s tallest building. So it is no surprise that ECOPlanet – the company’s global range of low-carbon cement – has been launched in 27 markets and now represents 60% of net sales in North America.iii

Holcim’s “green concrete” products use materials such as recycled aggregates, fly ash, and slag, which would otherwise end up in landfills. By using recycled materials, Holcim is promoting circular economy principles and reducing waste. The company is also developing new products, such as carbon-neutral concretes, which are designed to absorb CO2 during their lifetime and contribute to reducing carbon emissions.

Source: Holcim Capital Markets Day 2021

Holcim’s commitment to building circular cities extends beyond its own operations. The company has established partnerships with other stakeholders, including municipalities, to promote sustainable urban development. For example, Holcim has partnered with the City of Madrid to promote the use of sustainable construction materials in urban development projects. The company is also involved in the European Circular Cities Declaration, which aims to accelerate the transition towards a circular economy in European cities.

Holcim’s sustainability efforts have not gone unnoticed. In 2020, the company was named the world’s most sustainable company in the construction materials sector by Dow Jones Sustainability Indices (DJSI). The DJSI assesses companies based on their economic, environmental, and social performance, and Holcim’s top ranking reflects its strong sustainability practices and commitment to creating value for all stakeholders

As investors, we agree that it is essential to consider a company’s sustainability efforts when making an investment. However, we do not agree with cancel culture or the exclusionist approach as a means to an end. Instead, we prefer to collaborate with these companies to ensure that they are taking the proper steps to truly improve their sustainability credentials. Holcim is an excellent example of how a business can adapt and modify its strategy to promote a long-term, sustainable environment whilst providing attractive returns for its shareholders.

Footnotes

1 Scope 1 Emissions = All emissions directly from operations. Scope 2 Emissions = indirect emissions from consumer electricity. Scope 3 Emissions = All other indirect emissions generated via the supply chain

Sources

i Source: https://d3.harvard.edu/platform-rctom/submission/increasing-sustainability-in-cement-production-and-construction-sector/

Net Zero – A target of completely negating the amount of greenhouse gases produced by human activity, to be achieved by reducing emissions and implementing methods of absorbing carbon dioxide from the atmosphere.